OYN: Excellence in Pedestal Sink Manufacturing & Design

Discover High-Quality Craftsmanship at OYN: Your Premier Destination for Top-Rated Pedestal Sinks

At OYN pedestal sink factory, you can learn about the details of every process we go through while manufacturing the products. If you are searching for the best pedestal sink manufacturing company, the best way is to search online because you can also look at the views and reviews.

Various pedestal sink designs are available to match any home, which has led to rapid growth in the market in recent years. Sinks with great looks and functional advantages are becoming more and more popular. Come to us to get high-quality, reliable, and top-rated pedestal sinks in different varieties.

Main Features of OYN Pedestal Sink Manufacturing

Apply Precision-Formulated Clay and Slip

The clay for slip is adjusted as needed when formulating. Most time, the slip comprises 65% black porcelain clay and 35% white porcelain clay, giving the perfect texture required for the green body. Testing on the clay and slip for pedestal sinks are conducted until the desired characteristics are achieved. This testing includes slip viscosity, thickness, shrinkage, water absorption, and thermal properties.

Non-Splash Design

The OYN pedestal sink manufacturing company produces high-quality, durable, stylish sinks with its non-splash design. This technology ensures that water does not splash outside the ware, providing a clean and user-friendly experience. To ensure this is the case, we collaborate with our clients to determine which type of faucet will be installed. Splash-proofing is our chief priority regarding the pedestal sink because we know no one wants to get wet when using the sink. We keep aesthetic and practical at the same time when designing.

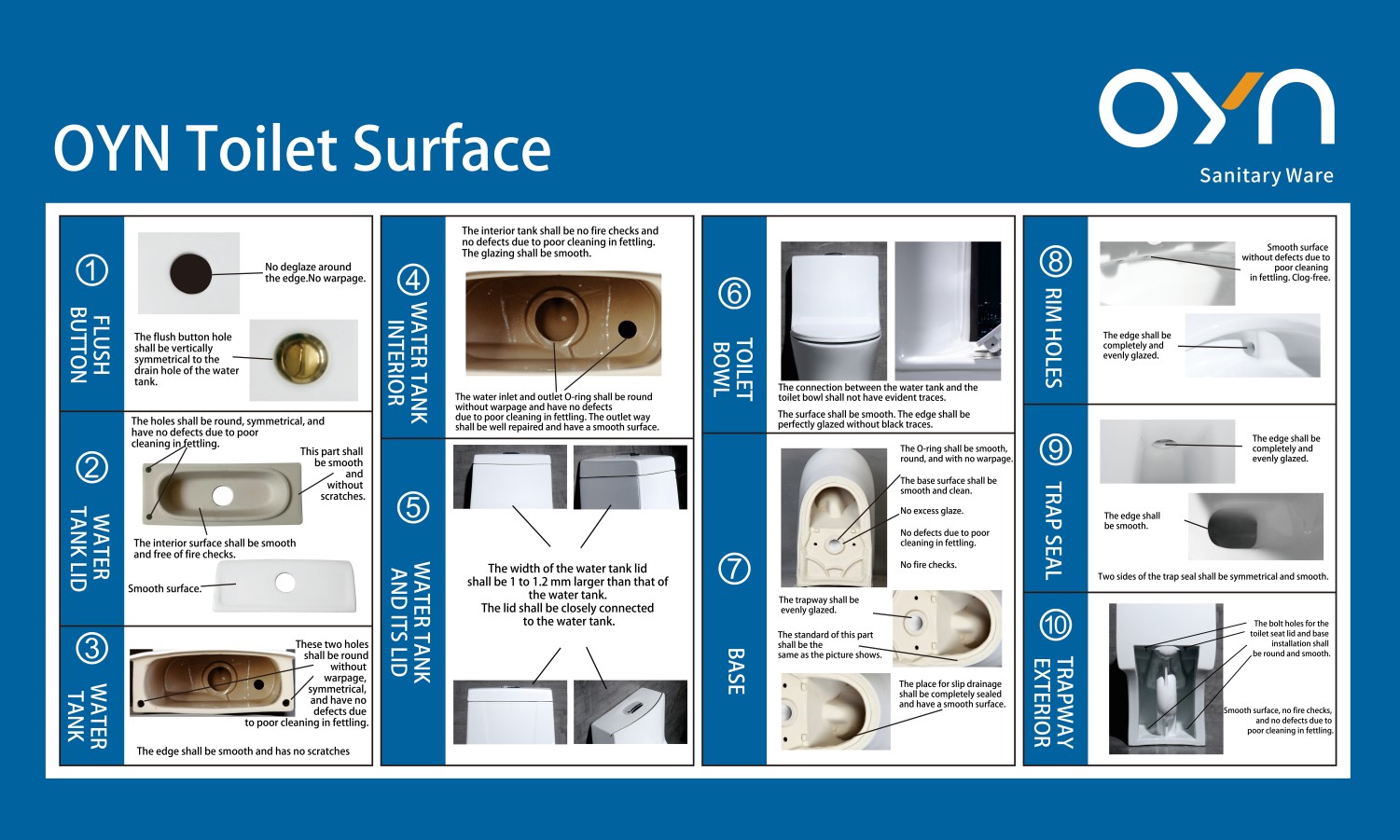

5 Coats of Glaze

Our priority in glazing the pedestal sink is ensuring the number of coats of glaze used in the glazing process to determine the safety and beauty of the pedestal sink. OYN applies 5 coats of glaze of 1.1 to 1.2mm thick on the green bode. However, most other manufacturers only use 2 to 3 coats of glaze with a thickness of 0.8mm. The 5-coat glazing is conducive to promising a flawless ceramic surface after firing because it is thick enough to cover or reduce the pinholes. Thus, it gives a surface without impurities.

Slip Casting Production Line

Our factory has a daily output of 600 pedestal sinks. There are two casting ways of producing two types of this ware.

With regard to the classic two-piece pedestal sinks, OYN applies battery casting respectively for its stand and sink.

For the gigantic modern one-piece pedestal sink, our factory uses a traditional way, bench casting. However, we improve it to decrease the requirement of manpower by adding mechanical parts to help move the molds. Though this way is not as efficient as battery casting, it is great for processing sinks that come in a complicated design. We are also seeking the possibility of applying high-pressure casting to make this type of sink.

Slip Heating and Electromotive Vibration

Slip formulation is finished with 35% white porcelain clay and 65% black one. Our lab conducts both slip as well as clay tests every day, including plasticity, permeability, viscosity, thixotropy, and so on in the laboratory to boost yield and product quality and keep stable shrinkage.

Thermostatic Casting Hall

OYN features a thermostatic casting hall for pedestal sinks, ensuring production stability because it is not influenced by the weather environment. In such a hall, the drying process is shortened after slip casting. Compared with the traditional production line, the ware output has increased by 30%.

Firing in Auto Shuttle Kiln

OYN utilizes an automated shuttle kiln for ware firing, integrated with a computerized system for enhanced production automation. This kiln, crafted by an industry-leading plant specializing in equipment export, costs around 290 thousand dollars, comparatively higher than most factories’ kilns, priced between 87 and 145 thousand dollars. Distinguished by excellent temperature control, our kiln is optimal for fabricating precision pedestal sink ceramics that demand stringent temperature regulation. Its multiple control zones ensure precise temperature increments and uniformity throughout the firing process.

100% Straightness Test and No Warpage Against the Wall

Quality control at OYN includes rigorous checks to maintain the straightness of pedestal sinks. We conduct three key inspections: post-demolding, post-drying, and post-glazing but pre-firing. Each stage ensures structural integrity, compliance with standards, and reduces warpage. All sinks must pass these checks before entering the firing area.

To guarantee the sink fits snugly against the wall, we utilize a specific instrument for flatness and straightness testing. Any deviations are rectified by trimming the sink base with an electric rotating tool, thus preventing post-sale issues.

OEM/ODM Services Aligned with Global Inspection Standards

OYN can customize the pedestal sinks according to the inspection standards of different countries. Our professionals will work closely with you to create a product that meets your needs and criteria. The production process is strictly monitored to ensure that the product meets the destination country’s quality standards and safety regulations. We can also provide additional services such as product packaging, labeling, and delivery services to ensure the timely arrival of your order.

Client-Selected Packaging Accepted

OYN pedestal sink manufacturer provides custom and safe packaging to ensure the safe delivery of our products. The packaging protects the sink from any damage during shipping and handling. We can use a combination of bubble wrap, foam, cardboard, and wooden box to ensure the sink is adequately protected. You may also ask us to use a crate for extra protection.

what we Offer

Product List

Exploring Why OYN is a Leading Pedestal Sink Manufacturer in the Market?

One-Stop OEM/ODM Sink Development

OYN’s short development cycle for pedestal sink manufacturing presents a distinct advantage for customers. Our substantial OEM and ODM experience, paired with in-house capabilities, facilitate swift, high-quality product development tailored to customer needs. Moreover, owning a mold factory and ceramic process plant enables us to oversee the entire development process, from preparing raw materials to in-house inspections. Consequently, this complete control further accelerates our development cycle.

Automation Driven High Efficiency

Amidst factory expansion and technological advancements, OYN Sanitary Ware strategically integrates production automation with manpower. This is evident in slip processing, where we employ a slip heating system and an electromotive vibration machine to eliminate bubbles, enhancing the slip’s suitability for casting. In slip casting, our innovative approach combines battery casting and high-pressure casting, tailored to specific products to boost output capacity. Post-casting, we utilize electronic spinners for efficient trimming of the green body. During the firing stage, automation shuttle kilns are used. Collectively, these state-of-the-art equipment not only elevate product quality but also augment productivity.

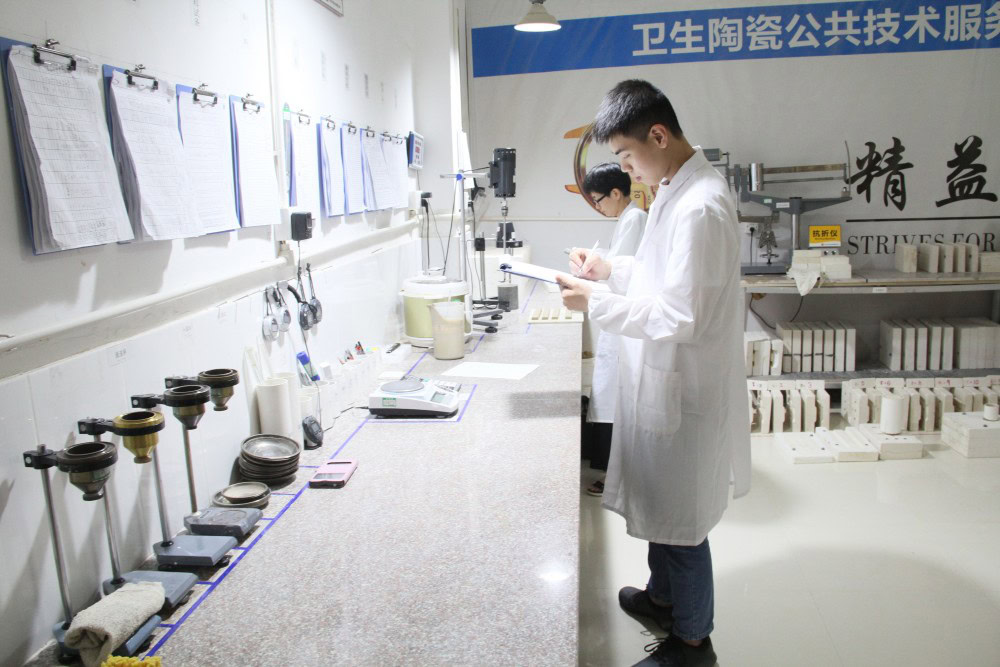

Raw Materials are Comprehensively Lab-Tested In-House

With the commitment to be a trusted manufacturer in the sanitary ware industry, OYN’s raw materials are rigorously tested in in-house laboratories to ensure the quality of the products. Tastings are started from the raw material discharge area up to dispatch. These tests are very important for maintaining a low rejection rate in production since we can discover problems in time.

For the original clay materials, tests on alkali demand, residue, shrinkage, loss of ignition (LOI), water absorption, casting rate, MOR, iron, moisture, and cone are needed.

And for mold making, we test the plaster material in order to decrease its porosity, which is good for the smoothness of the green body.

To ensure the slip quality for casting, our lab tests its pH, viscosity, density, flow, thixotropy, residue, and shrinkage. The parameters of the liquid, solid content, binder, wetting agent, deflocculant, sintering aid, mixing procedure, aging, deairing, and screening are carefully controlled.

After slip casting and during the drying process, we test the greenware’s density and humidity to make sure it can be accepted into the glazing process.

Glaze test includes density, viscosity, drying time, flow test, color matching, residue test, PSD test.

After firing, the ware will be tested with regard to its water absorption, crazing test, thermal shock resistance, and citric/ chemical resistance.

Certificates for Different Markets

As a sink supplier, OYN pedestal sinks are certified with CUPC, WaterSense, CE, and WATERMARK to ensure their standard and quality. Moreover, our factory has got ISO9001:2000. The products made by us meet the highest standards of quality and performance and complies with various legal and technical requirements. This allows us to offer our buyers confidence in the reliability and safety of our products.

Well-Arranged Manufacturing Plan for On-Time Delivery

OYN’s working system ensures stable, on-time, and reliable deliveries. To implement the production plan, we pre-plan everything from picking up the raw materials safely to delivering the finished wares. Considering any upcoming hurdles, we even make a Plan B with our clients to implement for emergencies.

We aim to establish and keep long-term cooperative relationships with our clients and work with them to keep everything up to the mark. None of our deliveries are late or damaged because we always choose reliable third-party shipping or express companies. The sole purpose of these companies is to keep a check and balance throughout the delivery process.

We know timely production means on-time delivery of the sanitary ware to the customer. That’s why we strengthen material management. Ensuring a never-ending supply of raw materials, we add up to our successful delivery promise without delay. Over the years, we’ve optimized the production process by adding advanced automation like battery casting and HPCM to quicken the ceramic processing. For smoothness in product quality and fast delivery, we conduct barcode tracking to get accurate data about inspections and rejection defects. This system is the essence of our years of efforts and expert team members.

Exceptional Quality at an Affordable Cost

Recognizing the long-term use and quality demands of pedestal sinks, our team strives to produce impeccable wares. This not only provides cost savings and increased ROI for our clients but also facilitates their business expansion and customer attraction.

In line with our mission, we deliver functional sinks offering value for money. By employing advanced techniques like the 5-glaze procedure, we ensure each product passing inspection embodies exceptional quality. Ultimately, our goal is to bolster our client’s success by offering an optimal blend of quality, performance, and value.

.

Seamless Post-Purchase Assistance

OYN pedestal sink manufacturer provides immediate and reliable support to our clients, including professional installation services and regular maintenance plans. We also offer an extended 5-year of warranty for all our ceramic sinks, ensuring clients have peace of mind regarding their batch purchases.

Here we provide comprehensive customer support, including technical support, product information, and troubleshooting. Our commitment to presenting the best after-sales service is unmatched in the industry, making OYN the preferred factory for pedestal sinks.

98%

satisfied clients

1000

daily output

20+

R&D new models

29+

Win-win case

Contact Us to Know More

OYN pedestal sink manufacturer is a reliable supplier and offers cost-effective products for wholesalers. We offer a range of customization options, allowing clients to create their unique pedestal sinks. Our experienced engineers and designers work with clients to create a beautiful, functional ceramic product that fits their needs. Contact us for a quotation or any details you want to know.

What Types of Pedestal Sinks can OYN provide?

As a sink manufacturer with over 20 years of experience manufacturing high-quality, globally accepted pedestal sinks, OYN offers customization solutions for clients in the areas of design, color, shape, and size.

Design-Centric for Your Business Growth

If you have a particular design preference for your brand, do not worry because we specialize in brand-oriented pedestal sinks. Bring as many challenging designs as possible, and we will make it possible. You can get different-sized and designed pedestal sinks on custom orders based on our MOQ. Whether you need a simple or complicated surface design, OYN has professionals capable enough to make the designs flawless and worth it. Additionally, if you need a new design to add to your other products, we guide and help you with perfect designs.

Various Types Available to Meet Your Sales Goals

We deal with every client depending on their needs without imposing our designs. You get whatever you desire for your business from us. The three main types of pedestal sink we provide to our clients include one-piece, two-piece, and semi-pedestal sinks. We also manufacture custom molds for businesses dealing with ceramic products to help you get more accessible with their work. OYN experts can also add your customized logo or another branding on the products to make it suit and adjust your business.

Tailored Appearance

There are several options available for customizing the appearance of pedestal sinks. Colors and finishes are available in a variety of options. Among them are water transfer printing, gold plating, and color glaze, all of which are classics. Sinks can be shaped uniquely, such as rounded or rectangular wares. To make it unique for your business, you can add decorative fixtures to your pedestal sink, such as soap dishes, towel bars, and other accessories.